Raw materials: Iron ore, cooper ore, steel slag, slag, river stone, granite, basalt, quartz stone, diabase, etc in metallurgy, chemical industry, building materials, water conservancy, mining, construction, metal and nonmetal mine industry and SDM high efficiency cone crusher also have no requirements about the moisture, which is also suitable for any hard and brittle materials.

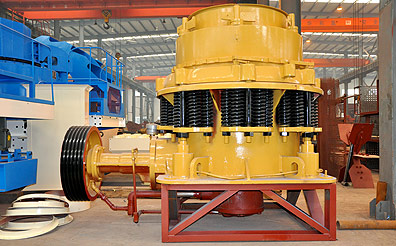

Features of SDM high efficiency cone crusher

1. Customers can choose suitable crushing cavity according to the material feature, finished product fineness and particle size requirement;

2. Unique dustproof and sealing structure extend cycle of lubricants replacement and spare parts service life;

3. The key parts are made of special materials, which support the strong crushing;

4. Long crushing arm, big stoke, strong crushing, and high capacity;

5. Hydraulic chamber cleaning system, easy operation, and reduce machine downtime;

6. Reliable performance, low investment cost, and long service life of quick-wear parts.

Specifications of SDM high efficiency cone crusher

| Model | Dia. mm (inch) |

Cavity | Feed pening |

Outlet Setting (mm) |

Shaft Speed (r/min) |

Power (kw) |

Capacity (t/h) |

Weight (t) | Dimension (mm) |

|

| Closing Side (mm) | Open Side (mm) | |||||||||

| SDMB3′ | 900 (3′) | Fine | 83 | 102 | 9-22 | 580 | 75 | 45-91 | 15 | 2821×1880×2164 |

| Coarse | 159 | 175 | 13-38 | 59-163 | ||||||

| Medium | 156 | 156 | 13-38 | 100-200 | ||||||

| Coarse | 178 | 191 | 19-51 | 141-308 | ||||||

| SDMB4.25′ | 1295 (4 1/4′) | Fine | 109 | 137 | 13-31 | 485 | 160 | 109-181 | 27 | 2800×2342×2668 |

| Medium | 188 | 210 | 16-38 | 132-253 | ||||||

| Coarse | 216 | 241 | 19-51 | 172-349 | ||||||

| SDMB5.5′ | 1650 (5 1/2′) | Fine | 188 | 209 | 16-38 | 485 | 220 | 181-327 | 55 | 3911×2870×3771 |

| Medium | 213 | 241 | 22-51 | 258-417 | ||||||

| Coarse | 241 | 268 | 25-64 | 299-635 | ||||||

| SDMB7′ | 2134 (7′) | Fine | 253 | 278 | 19-38 | 435 | 315 | 381-726 | 110 | 4613×3251×4732 |

| Medium | 303 | 334 | 25-51 | 608-998 | ||||||

| Coarse | 334 | 369 | 31-64 | 789-1270 | ||||||

Short Head

| Model | Dia. mm (inch) |

Cavity | Feed pening |

Outlet Setting (mm) |

Shaft Speed (r/min) |

Power (kw) | Capacity (t/hour) |

Weight (t) | Dimension (mm) |

|

| Closing Side (mm) | Open Side (mm) | |||||||||

| SDMD3′ | 914 (3′) | Fine | 13 | 41 | 3-13 | 580 | 75 | 27-90 | 15 | 2821×1880×2410 |

| Coarse | 33 | 60 | 3-16 | 27-100 | ||||||

| Medium | 44 | 73 | 10-16 | 90-145 | ||||||

| Coarse | 56 | 89 | 13-19 | 141-181 | ||||||

| SDMD4.25′ | 1295 (4 1/4′) | Fine | 29 | 64 | 3-16 | 485 | 160 | 36-163 | 27 | 2800×2342×2668 |

| Medium | 54 | 89 | 6-16 | 82-163 | ||||||

| Coarse | 70 | 105 | 10-25 | 109-227 | ||||||

| SDMD5.5′ | 1676 (5 1/2′) | Fine | 35 | 70 | 5-13 | 485 | 220 | 90-209 | 55 | 3917×2870×3771 |

| Medium | 54 | 89 | 6-19 | 136-281 | ||||||

| Coarse | 98 | 133 | 10-25 | 190-336 | ||||||

| SDMD7′ | 2134 (7′) | Fine | 51 | 105 | 5-16 | 435 | 315 | 190-408 | 110 | 4130×3251×4454 |

| Medium | 95 | 133 | 10-19 | 354-508 | ||||||

| Coarse | 127 | 178 | 13-25 | 454-599 | ||||||

Note: The production is based on open-circuit condition when bulk density of feeding is 1.6t/ m3. It is also relative to physics character,type of feeding, input size and composition etc. Sandmine machinery reserves all rights to change data without notice.