Application of Heavy duty Apron Feeder

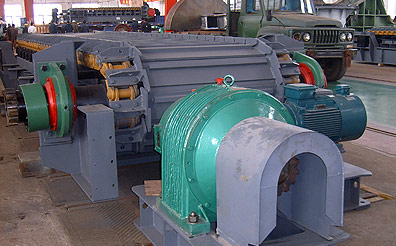

Sandmine apron feeder is engineered for heavy-duty operation and for primary or subsequent application stages. These custom-built machines are designed to suit individual requirements of capacity, size and material handled.

Features of Heavy duty Apron Feeder

1. Impact loads are absorbed by pans of rolled alloy/ cast alloy/ manganese steel material depending on application and are similar to heavy-duty track-type undercarriage shoes.

2. Pans are bolted to forged link chains supported on heavy-duty lifetime lubricated rollers. High strength pans resist abrasion and withstand heavy impact loads.

3. Short pitch and precision-machined chain provides noise-free discharge of material with negligible impact on receiver.

4. Chain and roller flanges maintain rigid alignment of pans in relation to skirt.

Specifications

| Type | Specification | Link speed (m/s) |

Feeding size (mm) |

Capacity (m3/h) |

Power (KW) |

Overall dimension (mm) |

Weight (kg) |

|

| Link joint (mm) |

Distance between shafts(mm) | |||||||

| GBZ100-6 | 1000 | 6000 | 0.016~0.05 | ≤450 | 16.6~50 | 15 | 7830×3718×980 | 21050 |

| GBZ100-8 | 8000 | 9800×3718×980 | 27440 | |||||

| GBZ100-10 | 10000 | 18.5 | 11800×3718×1100 | 34310 | ||||

| GBZ100-19 | 19000 | 21466×3718×1750 | 65190 | |||||

| GBZ110-6 | 1100 | 6000 | 0.022~0.065 | ≤400 | 50~150 | 7.5 | 7730×5168×1186 | 20285 |

| GBZ125-8 | 1250 | 8000 | 0.021~0.064 | ≤600 | 33.3~100 | 18.5 | 9180×3841×990 | 27136 |

| GBZ125-10 | 10000 | 11800×3841×990 | 33920 | |||||

| GBZ125-12 | 12150 | 13570×3841×990 | 34677 | |||||

| GBZ150-8 | 1500 | 8000 | 0.023~0.07 | ≤800 | 180~200 | 22 | 9840×4274×1160 | 29400 |

| GBZ150-15 | 15000 | 16592×4274×1160 | 46602 | |||||

| GBZ160-27 | 1600 | 27000 | 0.068 | ≤850 | 200 | 37 | 30065×2630×2240 | 119333 |

| GBZ180-10 | 1800 | 10000 | 0.02~0.07 | 333.3~500 | 37 | 13140×4964×3295 | 53303 | |

| GBZ200-10 | 2000 | 0.026~0.08 | ≤1000 | 83~250 | 45 | 11831×4640×1604 | 57390 | |

| GBZ220-10 | 2200 | 64000 | ||||||

| GBZ230-10 | 2300 | 0.05~0.09 | 190~340 | 55 | 11997×5602×1700 | 74500 | ||

| GBZ240-12 | 2400 | 12000 | 0.12 | ≤1200 | 1100 | 2×55 | 14316×7678×1700 | 111750 |

| GBZ340-8 | 3400 | 8000 | ≤1500 | 1900 | 2×42 | 9635×7250×1568 | 99615 | |

Note: The production is based on open-circuit condition when bulk density of feeding is 1.6t/ m3. It is also relative to physics character,type of feeding, input size and composition etc. Sandmine machinery reserves all rights to change data without notice.